Emulsification module

Aquamarijn offers microsieves optimized for emulsification with hydrophobic or hydrophilic coatings for making WATER in OIL or OIL in WATER emulsions respectively.

Watch a video of OIL in WATER emulsification

Watch a video of WATER in OIL emulsification

A cross-flow module made of stainless steel is available. For emulsification with strong solvents, we offer perfluoro elastomer (FFKM) O-rings. Solvent-resistant glue will be used to mount the chip onto a disc mount. Altogether, this makes the module fully solvent-compatible. Different designs & materials and a start-up kit & scaled-up module are available upon request. Contact us for a quote.

Description

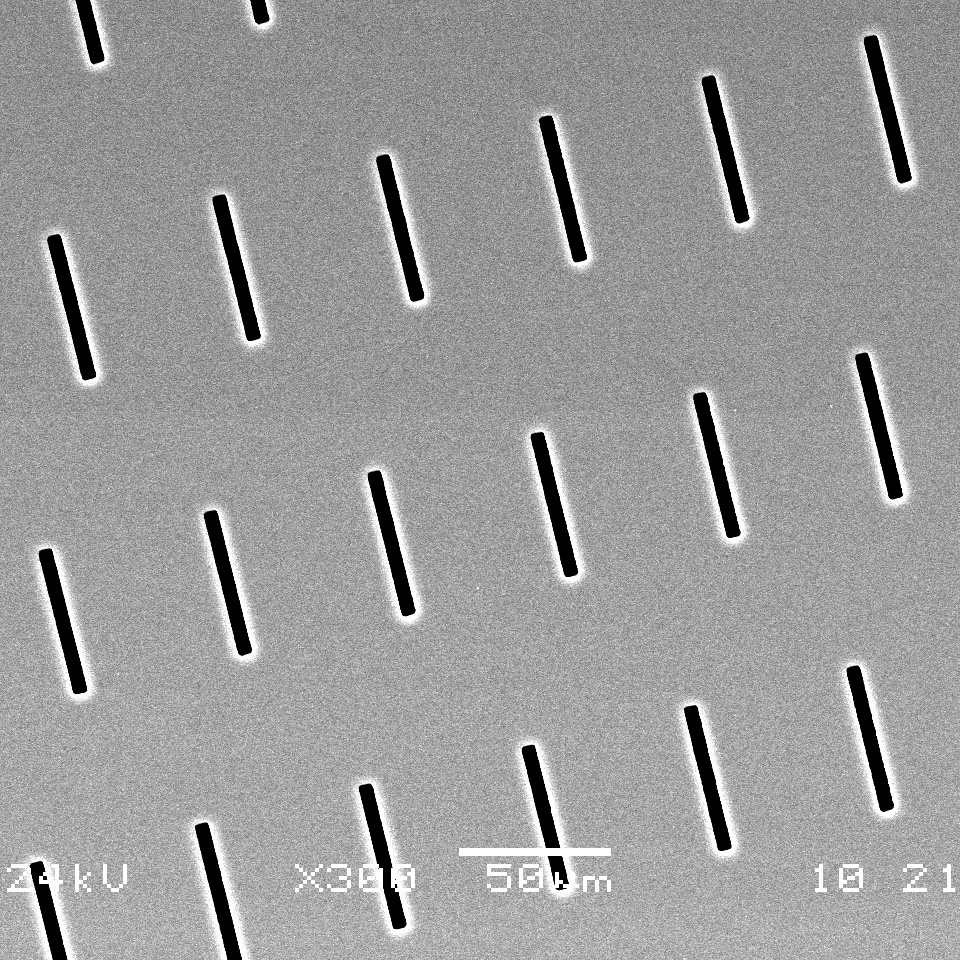

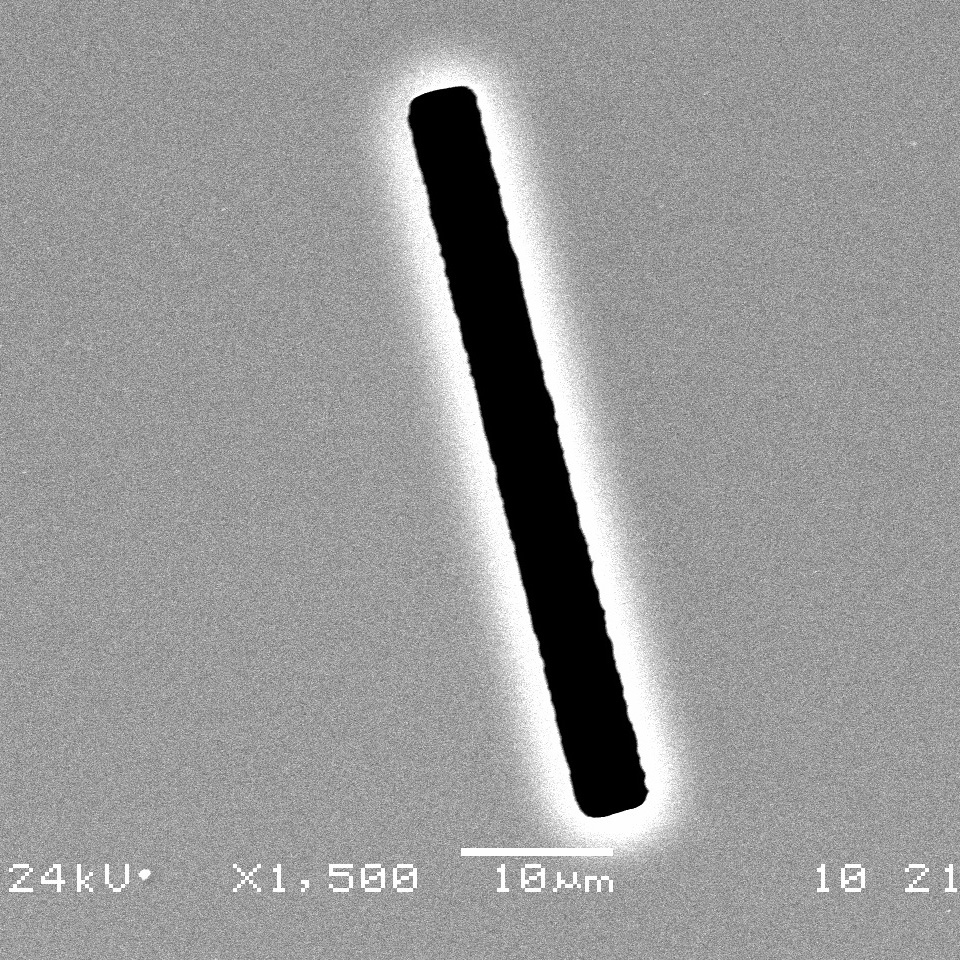

The microsieve membrane emulsification process generates monodisperse droplets by dispersing one fluid into a second, immiscible fluid through a precise microsieve. Thanks to the homogeneity of pore size, every droplet generated by the microsieve membrane is the same. In addition, hydrophobic or hydrophilic coatings for making WATER in OIL or OIL in WATER emulsions respectively, advances and stabilizes the process of emulsification. Altogether this results in highly uniform, reproducible and size-controlled droplets. The droplets can be transformed into particles after an appropriate solidification step.

In principle, the size of the droplet will be about 4 times larger than the width of the slit chip. It means:

o Slit chip 2×20 ⇒ ~ 8µm droplets

o Slit chip 3×30 ⇒ ~12µm droplets

o Slit chip 5×50 ⇒ ~25µm droplets

Additionally, membrane emulsification also can be performed with a low porosity membrane. In this case, the droplet size will be determined by the flow rate of the continuous flow. Contact us for technical support.

Microsieves Specification

| Type | Shape | Inner diameter (µm) | Outer diameter /length (µm) | Width (µm) | Pitch | Nozzles per chip |

|---|---|---|---|---|---|---|

| 2x20 | Slit | 20 | 2 | 9504 | ||

| 3x30 | Slit | 30 | 3 | 4224 | ||

| 5x50 | Slit | 50 | 5 | 1456 |

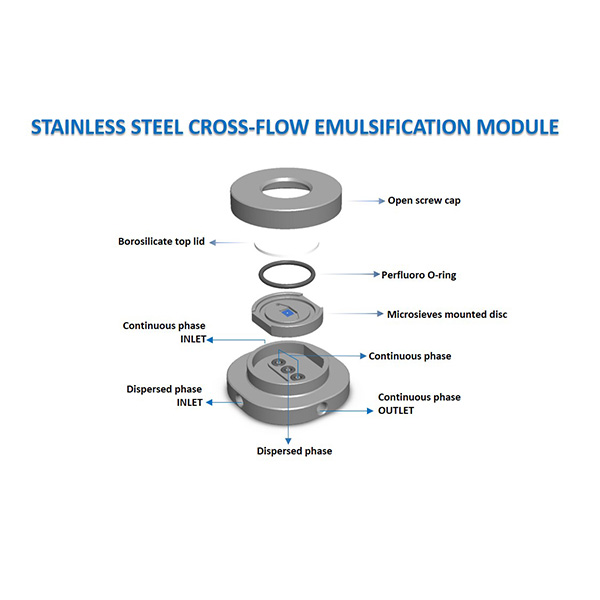

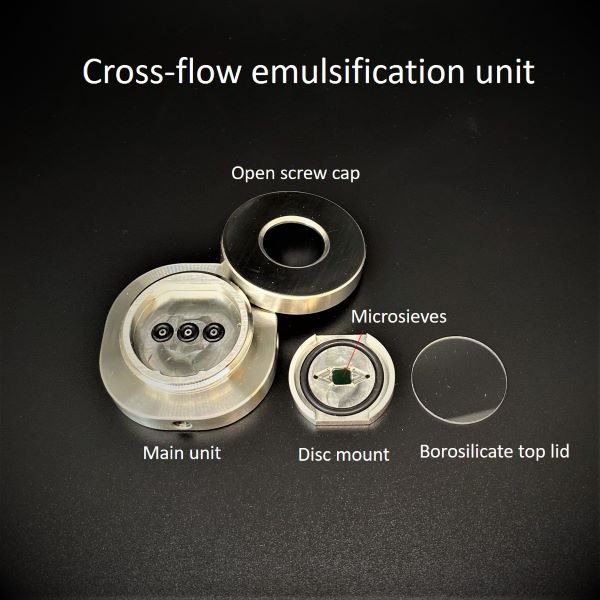

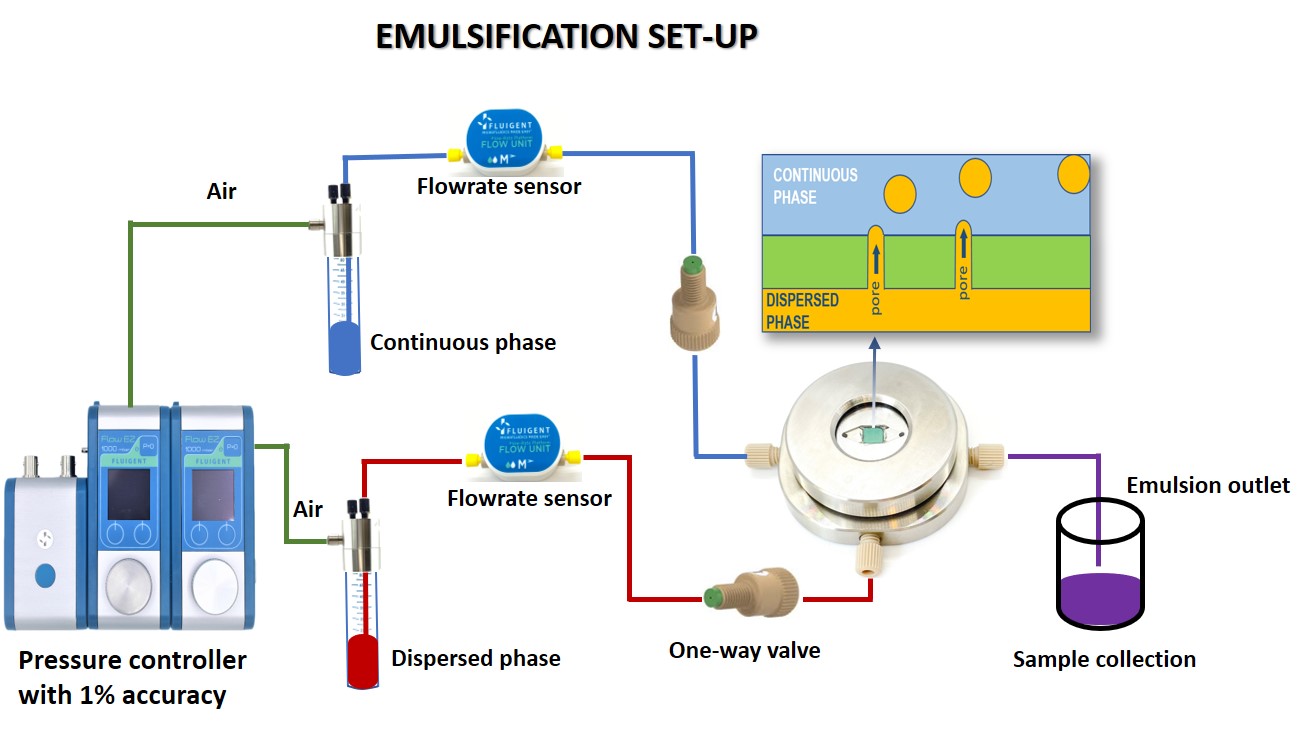

Cross-flow emulsification unit

Cross-flow emulsification unit

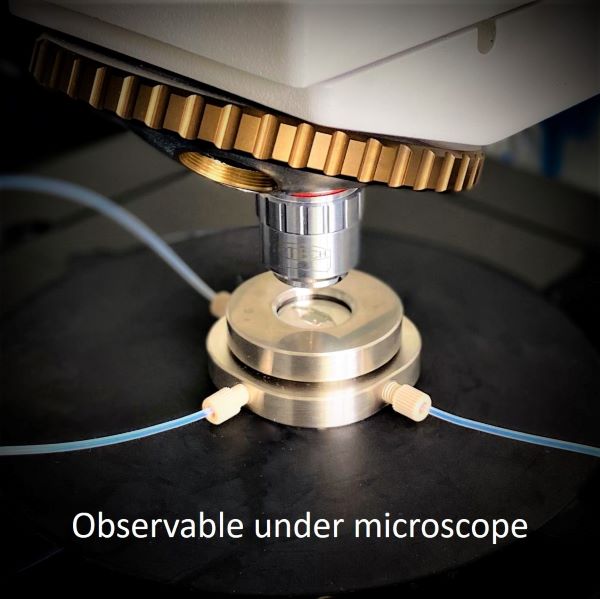

- The cross-flow emulsification module is a great tool for studying droplet formation, emulsion as well as membrane emulsification process (see video of droplet formation by microsieves ). Furthermore, the droplets can be transformed into particles after an appropriate solidification step.

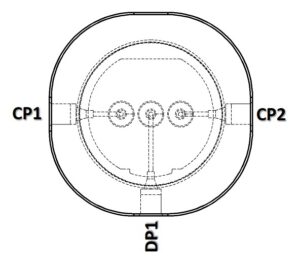

- The module has 3 in/outlets that fit with standard coned 10-32 threaded connectors. The borosilicate glass window allows observation of the droplet formation with a reflected light optical microscope. The module consists of the main unit made of stainless steel, borosilicate top lid and PEEK Nano Tight Fittings (or Luer Lock connectors), and Nitrile O-rings. For strong solvent applications: solvent-resistant glue will be used for mounting the chip onto disc mount and perfluoro O-rings will be used which altogether made the module fully solvent-resistant.

- For fluid connections, Nano Tight fittings (3 items) and 1/16” OD PTFE tubing (2 meters) are provided.

- All the channels in the module are as followed:

DP1: Dispersed Phase inlet

CP1: Continuous Phase inlet as cross-flow inlet

CP2: Continuous Phase outlet as emulsion outlet

Slit chips can be 2×20; 3×30 or 5×50 (see specifications)

- Accurate and stable flow for both the dispersed phase and continuous phase are important for the droplet formation process. Therefore, we recommend to use a syringe pump or a microfluidic flow controller to control the flow rate.

With proper cleaning and maintenance, the module can be reused many times. Improper cleaning after used may leave deposits inside the channels and the pores of the emulsifying chip which could result in clogging and poor performance of the chip. Under all circumstances do not touch the chip surface or sonicate the disc mount and ensure a particle-free working environment to prevent damage or clogging of the membrane.

INSTRUCTION VIDEOS: